Week 4

Part 1

I created this part by adding straight lines to 2 circles and then trimming off part of the circles. Later on when I checked the mass in the quiz I realized my mass is wrong. So I went back to check what is wrong but I couldn't... frustrated. I decided to redo.

this time, I used the arc tool and after adding the relations, it worked!

Part 2:

Part 5:

Using "power trim" tool to create this locking disk by trimming off the second circle and the intersection part of both circles.

Part 6:

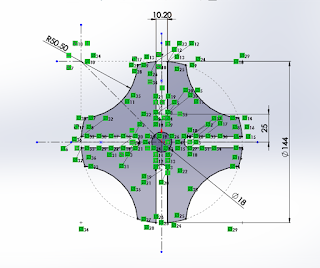

Hardest part in this exercise: the Geneva wheel. Spent 2 hours to get this done!

At first I sketched the upper left quarter and then mirroring it without thinking much but then the slots become under defined (blue lines) even when I added the dimensions. The tutor helped me solved this by adding "tangent" relation to the cutted slots and that fixed it. Also, she zoomed in and found additional lines sticking out of the "circle" and trimmed it off. Yet, after extruding it and changing the material, the mass is wrong.

No matter how I stare at it I couldn't find the problem so I just decided to redo the whole thing. And then another problem pops up.

I wanted to change the length of the line to 100mm but Solidworks wouldn't let me do it. Devastated, I asked for help. After quite some time searching for the problem she suggested me to make sure the sketch is fully defined before I mirror it, and redoing that would be much easier than finding the problem (the number of relations is just to overwhelming). And so I did. This time, even though all the lines were black, its still showing as under defined in the bottom tab. After another frustrating troubleshooting with the tutor, she finally fixed it. The key was to deselect the centerline (axis of mirror) and construction lines when mirroring the sketch.

Happily I extruded the sketch and then realized the mass is still incorrect. UGHHH.

It turned out that I dint select both of the contours (the whole thing and the small circle) when extruding, AND FINALLY ITS DONE.

Part 7:

Using the polygon tool to create a 12 sided polygon and making the 2 points at the top "horizontal: related to fully define the polygon. Then adding circles using circular pattern tool and a square using center point rectangle tool. Next, making sure the circles are fully defined by adding collinear relation with the centerline.

I was told that trimming off the slot and mirroring the part is tricky because the some relations in the slot is lost. And the lesson of the day was to fully define the sketch before mirroring it so that the final result would be fully defined.

Solidworks is indeed a very powerful tool yet it could be VERY frustrating when it doesn't really tells you where the problem is when something goes wrong. (sometimes)

Hopefully when the exercises get harder and harder I could be more patience and try not to smash my laptop.

I created this part by adding straight lines to 2 circles and then trimming off part of the circles. Later on when I checked the mass in the quiz I realized my mass is wrong. So I went back to check what is wrong but I couldn't... frustrated. I decided to redo.

this time, I used the arc tool and after adding the relations, it worked!

Part 2:

basically just repeating the same method, just adding "tangent" relations to the lines. No problem!

Part 3:

Creating a slot, and adding "equal" relation to the circles to make sure they have the same diameter.

Part 4:

Using mirror entities to create wide flange beam by mirroring the sketch about the 2 centerlines. At first I ctrl+clicked all the lines one by one to select them and then I was taught to just drag a window over the lines and TADAAA! everything selected.

Using "power trim" tool to create this locking disk by trimming off the second circle and the intersection part of both circles.

Part 6:

Hardest part in this exercise: the Geneva wheel. Spent 2 hours to get this done!

At first I sketched the upper left quarter and then mirroring it without thinking much but then the slots become under defined (blue lines) even when I added the dimensions. The tutor helped me solved this by adding "tangent" relation to the cutted slots and that fixed it. Also, she zoomed in and found additional lines sticking out of the "circle" and trimmed it off. Yet, after extruding it and changing the material, the mass is wrong.

I wanted to change the length of the line to 100mm but Solidworks wouldn't let me do it. Devastated, I asked for help. After quite some time searching for the problem she suggested me to make sure the sketch is fully defined before I mirror it, and redoing that would be much easier than finding the problem (the number of relations is just to overwhelming). And so I did. This time, even though all the lines were black, its still showing as under defined in the bottom tab. After another frustrating troubleshooting with the tutor, she finally fixed it. The key was to deselect the centerline (axis of mirror) and construction lines when mirroring the sketch.

Happily I extruded the sketch and then realized the mass is still incorrect. UGHHH.

It turned out that I dint select both of the contours (the whole thing and the small circle) when extruding, AND FINALLY ITS DONE.

Part 7:

Using the polygon tool to create a 12 sided polygon and making the 2 points at the top "horizontal: related to fully define the polygon. Then adding circles using circular pattern tool and a square using center point rectangle tool. Next, making sure the circles are fully defined by adding collinear relation with the centerline.

I was told that trimming off the slot and mirroring the part is tricky because the some relations in the slot is lost. And the lesson of the day was to fully define the sketch before mirroring it so that the final result would be fully defined.

Solidworks is indeed a very powerful tool yet it could be VERY frustrating when it doesn't really tells you where the problem is when something goes wrong. (sometimes)

Hopefully when the exercises get harder and harder I could be more patience and try not to smash my laptop.

Comments

Post a Comment