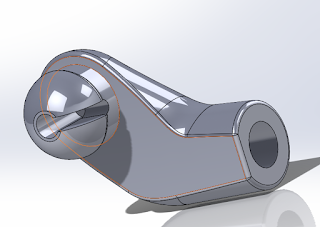

Lego man's arm

The most complicated part: the arm. Followed the tutorial video step by step to build this.

using Tools> Sketch tools> sketch picture to insert photo of the arm, aligning it to the origin and sketch according to the given dimensions with reference to the photo.

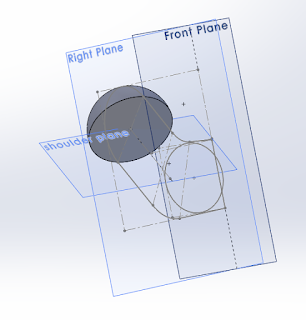

Adding "shoulder plane" with reference to a parallel line on the right plane, draw a slant line and extrude cut the sphere.

Sketching a circle in a guide square on front plane. Since the square is sketched from the first sketch on right plane, and the circle is at tangent to 3 edges, there is no need to dimension any lines.

Adding 2 more planes

Sketching another circle using same method as previous circle.

Create a loft from the 2 circles.

Sketch a line on the right plane and extrude cut (through all both sides).

Insert>Cut>with surface and select right plane to cut off parts beyond right plane.

Sketch on new plane and create a loft.

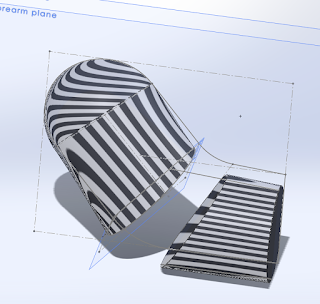

View> Display> zebra strips. Observation: the stripes are not joined together.

Solution: When creating the loft, select End constraints>tangency to face

Check with zebra stripes again, problem solved!

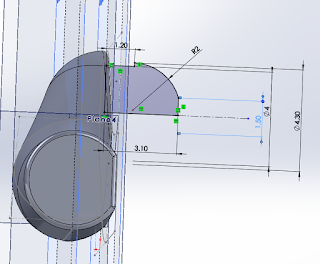

Adding a loft between 2 faces, using 2 guided lines and select both start and end constraints to be tangency to face. Problem: Clicked OK but Solidworks does not allow me to perform the loft.

Solution: When I was doing the extrude cut earlier somehow it doesn't cut through the whole part thus making the line for extrude cut longer solved the problem.

Loft created!

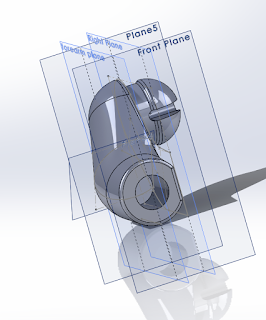

Adding fillets.

Add a plane and sketch the shoulder joint.

revolve the feature and add fillets.

Extrude cut a hole in the shoulder joint. Problem: something doesn't look right....

Solution: Sketched the wrong dimension in the first place. Corrected the dimension and then problem fixed

Draw a slot and extrude cut.

Last step (FINALLY) Roll back to before fillet is added, sketch and extrude cut a concentric circle from the front face.

DONE!!

Using Insert> mirror part to create left arm.

After thoughts: Although the steps are very complicated for a beginner like me, it is more accurate when the arm is created with reference of photo scan and built with lofts from different planes, instead of extruding and then cutting the parts later. It is also easier to manage than those online tutorial video I saw that uses a lot different tools that I've never learnt before.

Comments

Post a Comment