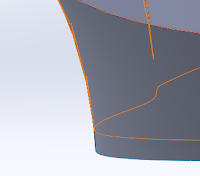

1. Middle housing: When I was doing this rib I had problem using cut with surface tool. I created boss extrude and wanted to cut the curve but it failed so I change the boss extrude to surface extrude but it failed as well. So I extrude cut from the middle plane instead and it worked. The middle housing is the first part I did. I was too OCD about putting all features from real mouse onto the model. Later I realized some features are not necessary because it doesn't interact with other parts in the assembly, and also I do not have the time to make my model perfectly accurate. 2. Battery cover After thicken, extruding surface and cut the sides, one face was missing and you can see through the part but this is a solid.... weird. It appears the same when I open the file in other computer as well. I couldn't fill surface because the boundary is not straight lines and there is a weird curve in the filled surface. I tried offsetting the cut surface in for abo...